Introduction

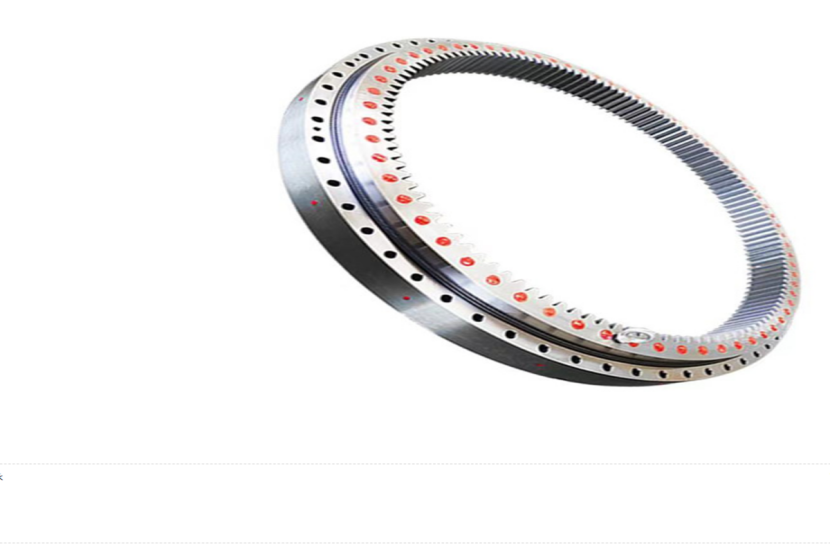

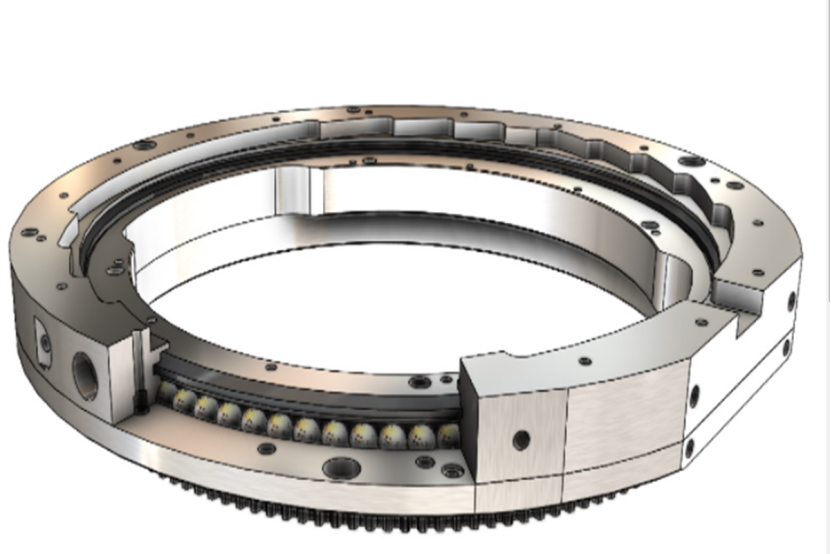

In the realm of machinery and equipment, the significance of slewing bearing suppliers cannot be overstated. These suppliers play a pivotal role in ensuring the smooth operation and functionality of various industrial applications, ranging from cranes to wind turbines. At the heart of their offerings lies the slewing bearing, a crucial component that facilitates rotational movement within machinery. This introductory section aims to delve into the importance of slewing bearing suppliers across different industries while providing a brief overview of the indispensable role played by slewing bearings in machinery and equipment.

Slewing bearings serve as the linchpin for rotational movement in a multitude of industrial applications. From aiding in the rotation of cranes to enabling the azimuth movement of solar panels, these bearings are integral to the functionality of diverse machinery. Their ability to withstand heavy loads, high speeds, and adverse environmental conditions makes them indispensable components in various sectors, including construction, renewable energy, mining, and transportation.

The role of slewing bearing suppliers extends beyond merely providing these essential components. They are tasked with delivering high-quality bearings that meet stringent industry standards while offering innovative solutions to address the evolving needs of their customers. With advancements in technology and engineering, slewing bearing suppliers continually strive to enhance the performance, durability, and efficiency of their products to cater to the demands of modern industrial applications.

As we delve deeper into this exploration of the top 17 slewing bearing suppliers in 2024, it becomes apparent that these companies play a crucial role in driving innovation, reliability, and progress across various industries. Their contributions not only ensure the seamless operation of machinery but also pave the way for advancements in industrial efficiency and productivity.

slewing bearing suppliers

1. SKF Group.

In the realm of slewing bearing suppliers, SKF Group stands tall as a global leader, setting benchmarks with its commitment to precision and durability.

Features:

SKF’s extensive line of slewing bearings showcases a spectrum of sizes, each meticulously crafted to meet the exacting demands of industrial applications. The hallmark of SKF’s offerings lies in their robustness and precision, ensuring optimal performance across varied scenarios.

Advantages:

1. Exceptional Load-Carrying Capacity: SKF’s slewing bearings are designed to bear substantial loads, making them a preferred choice for heavy-duty machinery and equipment.

2. High Rotational Accuracy: Precision is at the core of SKF’s design philosophy, resulting in slewing bearings that boast unparalleled rotational accuracy, crucial for applications requiring exact positioning.

2. Schaeffler Group.

In the dynamic landscape of slewing bearing suppliers, the Schaeffler Group stands as an epitome of precision engineering and innovation, revolutionizing the industry with its cutting-edge solutions.

Features:

At the core of Schaeffler’s offerings lie high-precision slewing bearings meticulously engineered to meet the diverse needs of both automotive and industrial sectors. These bearings, available in a multitude of configurations, boast exceptional quality and reliability, setting new standards in the industry.

Advantages:

1. Robustness Redefined: Schaeffler’s slewing bearings are crafted with a keen focus on durability, capable of withstanding extreme operating conditions with ease. This robustness ensures longevity and minimal maintenance requirements, making them a preferred choice across industries.

2. Precision at Its Peak: Precision is the hallmark of Schaeffler’s slewing bearings, underpinned by advanced manufacturing processes and stringent quality controls. This unparalleled precision translates into seamless operation and enhanced efficiency in every application.

3. Timken Company.

As we continue our exploration into the domain of elite slewing bearing suppliers, the spotlight now falls on the Timken Company, renowned for its commitment to engineering excellence and unmatched reliability.

Features:

At the heart of Timken’s offerings lie slewing bearings crafted with a meticulous blend of advanced engineering and premium materials. These bearings are meticulously designed to withstand the rigors of demanding applications, ensuring optimal performance even in the harshest environments.

Advantages:

1. Superior Load-Carrying Capacity: Timken’s slewing bearings are engineered to deliver exceptional load-carrying capacity, enabling them to support heavy loads with ease. This capability makes them ideal for a wide range of industrial and automotive applications where strength and reliability are paramount.

2. Corrosion Resistance: Timken’s slewing bearings are built to withstand the corrosive effects of various environmental factors, including moisture, chemicals, and extreme temperatures. This corrosion resistance ensures longevity and reliability, even in harsh operating conditions.

4. NSK Ltd.

As we delve deeper into our exploration of the top-tier slewing bearing suppliers, our focus now shifts to NSK Ltd., a global leader renowned for its cutting-edge roller bearing solutions and unwavering commitment to excellence.

Features:

NSK’s illustrious reputation in the realm of roller bearing manufacturing extends to its range of slewing bearings, meticulously engineered to meet the diverse needs of industrial and automotive sectors. These slewing bearings boast a myriad of features that set them apart in terms of quality, reliability, and performance.

Advantages:

1. High Load Capacity: One of the standout advantages of NSK’s slewing bearings is their exceptional load-carrying capacity. Engineered to withstand heavy loads, these bearings ensure reliable performance even in the most demanding operating conditions.

2. Rigidity: Rigidity is paramount in applications where precise positioning and stability are critical. NSK’s slewing bearings exhibit outstanding rigidity, providing the necessary support and stability for smooth operation and enhanced efficiency.

5. NTN Corporation.

In our quest to uncover the elite players in the slewing bearing industry, our attention now turns to NTN Corporation, a prominent manufacturer celebrated for its diverse range of high-quality bearings, including precision-engineered slewing bearings.

Features:

NTN’s portfolio encompasses a comprehensive array of bearings tailored to meet the exacting demands of various industrial applications. Among its offerings are slewing bearings distinguished by their robust construction, exceptional load-carrying capacity, and precision engineering. These slewing bearings are meticulously crafted to deliver superior performance in critical operations where accuracy and reliability are paramount.

Advantages:

1. Low Friction: NTN’s slewing bearings are designed to minimize friction, ensuring smooth rotational motion with minimal energy loss. This low-friction design not only enhances efficiency but also reduces wear and tear, prolonging the service life of the bearings.

2. High Reliability: NTN places a strong emphasis on reliability, and its slewing bearings are no exception. Built to withstand heavy loads and harsh operating conditions, these bearings offer unmatched reliability, providing uninterrupted performance even in the most demanding environments.

6.Xuzhou Wanda Slewing Bearing Co. Ltd.

Xuzhou Wanda Slewing Bearing Co. Ltd. is a renowned manufacturer and supplier of slewing bearings, renowned for its commitment to quality, innovation, and customer satisfaction. Let’s delve into the distinctive features and advantages of Xuzhou Wanda Slewing Bearing Co. Ltd.:

Features:

1. Diverse Product Range: Xuzhou Wanda offers a comprehensive range of slewing bearings designed to cater to a wide array of applications across various industries. From small- to large-diameter bearings, their product line encompasses single-row, double-row, and triple-row slewing bearings, ensuring compatibility with diverse machinery requirements.

2. Precision Engineering: Each slewing bearing manufactured by Xuzhou Wanda undergoes rigorous precision engineering processes to ensure optimal performance and reliability. With advanced technologies and state-of-the-art manufacturing facilities, they achieve high levels of accuracy and consistency in their products.

3. Customization Options: Recognizing the unique needs of different industries and applications, Xuzhou Wanda offers customization options for their slewing bearings. They work closely with clients to understand their specific requirements and tailor solutions that meet or exceed expectations, whether it’s modifying dimensions, load capacities, or sealing options.

Advantages:

1. High Load-Carrying Capacity: Xuzhou Wanda’s slewing bearings are engineered to withstand heavy loads and harsh operating conditions. Their robust construction and high-quality materials ensure exceptional load-carrying capacity, making them ideal for applications where reliability and durability are critical.

2. Enhanced Durability: Durability is a hallmark of Xuzhou Wanda’s slewing bearings. Utilizing premium-grade materials and advanced manufacturing techniques, they deliver bearings with superior wear resistance, corrosion resistance, and longevity. This translates to extended service life and reduced maintenance costs for end-users.

3. Reliable Performance: Customers rely on Xuzhou Wanda’s slewing bearings for their consistent and reliable performance. With stringent quality control measures in place at every stage of production, they guarantee bearings that meet stringent industry standards and exceed customer expectations for reliability and performance.

7. MinebeaMitsumi Inc.

MinebeaMitsumi Inc. stands as a leading manufacturer in the realm of slewing bearings, known for its commitment to precision engineering and innovative solutions tailored to the aerospace, robotics, and industrial sectors.

Features:

1. High Precision: MinebeaMitsumi’s slewing bearings are engineered with meticulous attention to detail, ensuring unparalleled precision in their design and manufacturing processes. This precision is crucial for applications where accuracy and reliability are paramount, such as aerospace and robotics.

2. Diverse Applications: The slewing bearings produced by MinebeaMitsumi find applications across a wide spectrum of industries, including aerospace, robotics, and industrial automation. Their versatility allows them to adapt to various environments and operational requirements, making them a preferred choice for diverse applications.

Advantages:

1. Compact Design: MinebeaMitsumi’s slewing bearings are characterized by their compact design, which allows for efficient use of space in constrained environments. This feature is particularly advantageous in aerospace and robotics applications where size and weight considerations are critical.

8. Nachi-Fujikoshi Corp.

Nachi-Fujikoshi Corp. stands out as a premier manufacturer of slewing bearings, renowned for its commitment to precision engineering and delivering high-quality solutions tailored to various industries.

Features:

1. Precision Engineering: Nachi-Fujikoshi’s slewing bearings are meticulously engineered to exacting standards, ensuring exceptional precision in their design and manufacturing processes. This precision is critical for applications requiring accurate positioning and smooth operation.

2. High Load Capacity: The slewing bearings produced by Nachi-Fujikoshi are designed to withstand heavy loads, making them suitable for applications where reliability and durability are paramount. Their robust construction ensures optimal performance even under challenging operating conditions.

Advantages:

1. Excellent Shock Resistance: Nachi-Fujikoshi’s slewing bearings offer outstanding shock resistance, making them suitable for applications where sudden impacts or vibrations are common. This resilience ensures stable performance and minimizes the risk of premature failure.

2. High Accuracy: Nachi-Fujikoshi places a strong emphasis on achieving high levels of accuracy in their slewing bearings, ensuring precise positioning and smooth rotational movement. This accuracy is essential for applications requiring precise motion control and alignment.

9. RBC Bearings Inc.

RBC Bearings Inc. is a leading manufacturer of slewing bearings, catering to a diverse range of industries including aerospace, defense, and industrial sectors. With a reputation for excellence and innovation, RBC Bearings delivers high-quality solutions tailored to meet the demanding requirements of modern applications.

Features:

1. Diverse Product Range: RBC Bearings offers a comprehensive range of slewing bearings designed to meet the specific needs of various industries. From compact designs for aerospace applications to heavy-duty bearings for industrial machinery, RBC Bearings provides solutions for a wide range of requirements.

2. Aerospace and Defense Focus: With a strong presence in the aerospace and defense sectors, RBC Bearings specializes in producing slewing bearings that meet stringent performance and reliability standards. Their bearings are utilized in critical aerospace applications, including aircraft landing gear systems and satellite antennas.

Advantages:

1. High-Speed Performance: RBC Bearings’ slewing bearings are engineered for high-speed applications, offering smooth and reliable operation even at elevated rotational speeds. This capability makes them ideal for machinery requiring precise and efficient motion control.

2. Heavy-Duty Durability: RBC Bearings’ slewing bearings are designed to withstand heavy loads and harsh operating environments, ensuring long-term durability and reliability. Their robust construction and advanced materials contribute to extended service life and reduced maintenance requirements.

10. THK Co., Ltd.

THK Co., Ltd. stands out as a prominent manufacturer of linear motion products, offering high-precision slewing bearings tailored for industrial automation applications. Renowned for their quality and innovation, THK’s slewing bearings play a crucial role in enhancing the performance and efficiency of automated systems.

Features:

Specialization in Linear Motion Products: THK specializes in the production of linear motion products, including slewing bearings designed to facilitate smooth and precise movement in automated machinery. Their expertise in this field allows them to develop advanced solutions tailored to the specific requirements of industrial automation.

Advantages:

1. High Rigidity: THK’s slewing bearings are renowned for their high rigidity, providing excellent support and stability for automated equipment. This rigidity minimizes deflection and ensures precise motion control, even under heavy loads or dynamic operating conditions.

2. Accuracy and Repeatability: With exceptional accuracy and repeatability, THK’s slewing bearings enable precise positioning and motion control in automated systems. This accuracy is essential for achieving consistent performance and maintaining product quality in industrial manufacturing processes.

11. ZWZ Bearings.

http://zwzbearingusa.com/ZWZ Bearings is a reputable manufacturer renowned for producing a diverse range of high-quality slewing bearings tailored for various industrial applications. With a commitment to excellence and innovation, ZWZ continues to uphold its position as a top supplier in the slewing bearing industry.

Features:

1. Diverse Product Range: ZWZ Bearings offers a comprehensive range of slewing bearings designed to meet the diverse needs of industrial machinery and equipment. Their product lineup includes both standard and customized solutions, catering to different load capacities, sizes, and operating conditions.

2. Quality Manufacturing: ZWZ is committed to maintaining stringent quality standards throughout the manufacturing process. Their slewing bearings are precision-engineered using advanced technologies and premium materials to ensure superior performance, durability, and longevity in various operating environments.

Advantages:

Reliability: ZWZ Bearings are synonymous with reliability, offering dependable performance and long-term durability. Built to withstand heavy loads, shocks, and vibrations, ZWZ slewing bearings provide a stable and reliable foundation for industrial machinery, ensuring uninterrupted operation and minimal downtime.

12. Luoyang LYC Bearing Co., Ltd.

Luoyang LYC Bearing Co., Ltd. is a distinguished manufacturer renowned for its expertise in producing large-sized slewing bearings tailored for heavy machinery and construction equipment. With a focus on precision engineering and superior quality, LYC Bearing continues to be a leading supplier in the slewing bearing industry.

Features:

Specialization in Large-Sized Bearings: LYC Bearing specializes in the production of large-sized slewing bearings, catering to the specific requirements of heavy machinery and construction applications. Their product portfolio includes a wide range of bearings designed to support heavy loads and facilitate smooth rotational movement in various industrial settings.

Advantages:

Precision and Stability: LYC slewing bearings offer precise rotational movement and stable operation, even under extreme loads and harsh environmental conditions. With their high degree of accuracy and stability, LYC bearings contribute to the efficiency and productivity of industrial machinery, minimizing downtime and maintenance costs.

13. CW Bearing USA, Inc.

CW Bearing USA, Inc. is a prominent manufacturer specializing in the production of high-precision slewing bearings. With a focus on innovation and quality, CW Bearing’s products find applications in various industries, including wind turbines, cranes, and more. Let’s delve into the features and advantages that set CW Bearing apart as one of the top slewing bearing suppliers of the year.

Features:

1. High-Precision Manufacturing: CW Bearing USA employs advanced manufacturing processes and state-of-the-art technologies to produce slewing bearings with exceptional precision. Their meticulous attention to detail ensures that each bearing meets stringent quality standards and provides reliable performance in critical applications.

2. Diverse Applications: CW Bearing’s slewing bearings cater to a wide range of industries and applications, including wind energy, construction, mining, and marine. Whether it’s supporting the rotation of wind turbine blades or facilitating the movement of heavy machinery in construction sites, CW Bearing’s products demonstrate versatility and adaptability.

Advantages:

1. Reliability: CW Bearing’s slewing bearings are renowned for their reliability and consistent performance. With precision engineering and quality craftsmanship, CW Bearing ensures that their bearings meet the demanding requirements of industrial applications, delivering reliable operation under diverse operating conditions.

2. Efficiency: CW Bearing’s slewing bearings are designed for optimal efficiency, minimizing energy consumption and maximizing productivity. By reducing friction and wear, these bearings contribute to the smooth and efficient operation of machinery, resulting in improved performance and reduced downtime.

14. Emerson Bearing Co.

Emerson Bearing Co. stands as a leading provider of slewing bearings, catering to diverse industries with a focus on precision and durability. Let’s explore the distinctive features and advantages that position Emerson Bearing as one of the top slewing bearing suppliers of the year.

Features:

1. Diverse Product Range: Emerson Bearing offers a comprehensive range of slewing bearings tailored to meet the needs of various industries, including aerospace, automotive, construction, and more. Their extensive product catalog ensures that customers can find suitable solutions for their specific applications, regardless of size or complexity.

2. Precision Engineering: Emerson Bearing’s slewing bearings are engineered with precision and attention to detail. Utilizing advanced manufacturing techniques and quality materials, these bearings exhibit tight tolerances and high accuracy, allowing for smooth and reliable operation even in demanding environments.

Advantages:

Smooth Operation: Emerson’s slewing bearings are designed for smooth and efficient operation, minimizing friction and vibration. This characteristic ensures smooth rotational movement, precise positioning, and enhanced overall performance of machinery and equipment.

15. C&U Group Co., Ltd.

C&U Group Co., Ltd. emerges as a prominent player in the slewing bearing industry, offering a wide array of solutions tailored to various applications. Let’s delve into the distinctive features and advantages that set C&U Group apart as one of the top slewing bearing suppliers of the year.

Features:

1. Versatile Product Range: C&U Group boasts a diverse portfolio of slewing bearings designed to cater to the needs of different industries. From construction machinery to renewable energy systems, their product range encompasses various sizes and configurations to accommodate a wide range of applications.

2. Precision Engineering: The slewing bearings manufactured by C&U Group are engineered with precision and expertise. Leveraging advanced technologies and stringent quality control measures, these bearings exhibit exceptional dimensional accuracy, ensuring precise alignment and smooth operation in demanding environments.

Advantages:

High Load-Carrying Capacity: One of the key advantages of C&U Group’s slewing bearings is their impressive load-carrying capacity. Engineered to withstand heavy loads and dynamic forces, these bearings provide robust support and stability, ensuring safe and efficient operation even in the most demanding working conditions.

- AST Bearings LLC.

Features:

Custom Solutions: AST Bearings specializes in providing custom-engineered slewing bearings to address specific customer requirements. Leveraging their expertise in bearing design and manufacturing, they offer tailored solutions that meet unique application challenges with precision and efficiency.

Advantages:

Exceptional Quality: AST Bearings is renowned for its commitment to quality and excellence. Their slewing bearings undergo rigorous quality control procedures to ensure compliance with industry standards and customer specifications, guaranteeing reliable performance and long service life.

- Samick Precision Ind. Co., Ltd.

Features:

Precision Manufacturing: Samick Precision Ind. Co., Ltd. specializes in the precision manufacturing of slewing bearings, ensuring tight tolerances and high accuracy in their products. Their commitment to precision engineering results in bearings that deliver smooth operation and optimal performance.

Advantages:

Superior Performance: Samick’s slewing bearings are known for their superior performance characteristics, including smooth rotation, low friction, and high efficiency. Designed to meet stringent performance requirements, these bearings ensure reliable operation and minimal downtime for end-users.

Market Trends and Future Outlook

In the dynamic landscape of the slewing bearing industry, it’s crucial to anticipate future trends and developments to stay ahead of the curve. As we delve into the predictions for the future and identify potential challenges and opportunities, we’ll explore how slewing bearing suppliers, including Xuzhou Wanda Slewing Bearing Co. Ltd., can navigate the evolving market landscape.

Technological Advancements: With rapid advancements in technology, the slewing bearing industry is expected to witness innovations in materials, manufacturing processes, and design. Emerging technologies such as additive manufacturing and advanced coatings are likely to revolutionize the production of slewing bearings, leading to improved performance and durability.

Demand for Sustainable Solutions: Environmental sustainability is becoming increasingly important in manufacturing processes. Slewing bearing suppliers will need to focus on eco-friendly materials and sustainable production methods to meet the growing demand for green solutions. This shift towards sustainability presents opportunities for companies to differentiate themselves in the market and appeal to environmentally conscious customers.

Integration of IoT and Data Analytics: The integration of Internet of Things (IoT) technology and data analytics into slewing bearings is poised to transform the industry. IoT-enabled bearings can provide real-time monitoring of performance metrics, predictive maintenance alerts, and valuable insights into equipment health. This data-driven approach enhances operational efficiency, reduces downtime, and prolongs the lifespan of machinery.

In summary, the slewing bearing industry is poised for significant transformations in the coming years, driven by technological advancements, sustainability initiatives, and evolving customer demands. By embracing innovation, addressing challenges proactively, and capitalizing on emerging opportunities, slewing bearing suppliers can position themselves for success in the dynamic market landscape of the future.

slewing bearing suppliers

Conclusion

In conclusion, the significance of slewing bearing suppliers cannot be overstated in the realm of industrial machinery. These suppliers play a vital role in ensuring the performance, reliability, and efficiency of various types of machinery across diverse industries. By providing high-quality slewing bearings, they enable smooth motion control and contribute to the overall functionality of industrial equipment.

Recap of Significance: Slewing bearing suppliers serve as essential partners for industries reliant on machinery, such as construction, mining, renewable energy, and manufacturing. Their products facilitate the movement and rotation of heavy loads, ensuring the smooth operation of cranes, excavators, wind turbines, and other machinery. The reliability and durability of slewing bearings are paramount for maintaining safety standards and maximizing productivity in industrial settings.